- Contact Us

- Call Us

- Menu

Ball valves are used throughout fluid-based applications, from residential to heavy industrial. The compact and rugged design of this valve type provides superior service when properly applied. There are many variants of the basic design, with manufacturers providing builds that meet very specific and stringent requirements posed by certain types of industrial process control applications.

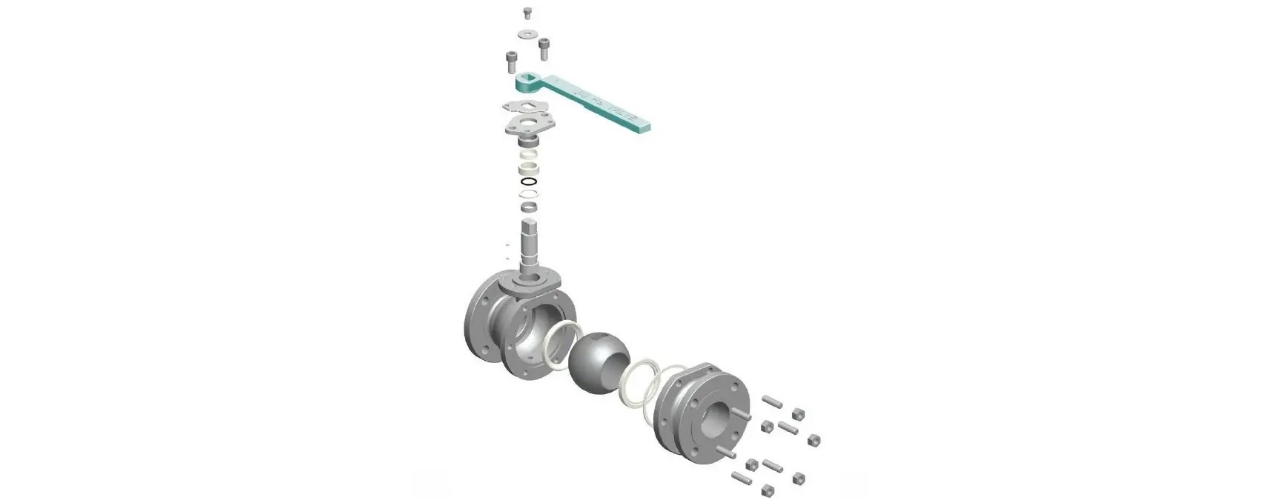

Ball valves are named for the spherically shaped element encased in the valve body directly in the fluid flow path. The ball has a hole, or port, through its center, permitting fluid to pass when the port is aligned with the direction of flow. A stem is attached to the ball and extends to the exterior of the valve body, providing a mechanical means of rotating the ball between open and closed positions. Ninety degrees of rotation move the ball from the fully open to the fully closed position. Ball valves are generally suitable for manual or automated operation.

In the basic design of ball valves, there are two groups that exhibit an essential structural difference that is worth mentioning. There are two ways in which the ball in a ball valve is held in place. A floating ball valve has its main trim element held in place by the shape of the valve body and the seats. It is essentially suspended in the flow path by its surrounding parts. A very small amount of lateral movement of the ball is imparted by the fluid flow, pushing the ball tightly against the seat on the downstream side. This attribute enables a floating ball valve to provide tight shutoff of bidirectional flow.

The floating ball design proves less effective as the nominal bore size increases. The added weight of the larger ball, coupled with the larger surface area exposed to fluid forces, can overcome the ability of the seals to properly support the ball and maintain good performance. The maximum size can vary among manufacturers.

Enjoying all the benefits of ball valve design, plus being comparatively simple to disassemble and service, floating ball valves are a solid choice for many industrial applications. Selecting the right valve design or type is an important step toward effective control of fluid operations. Share your fluid process control challenges with a valve expert, combining your process knowledge with their product application expertise to develop effective solutions.