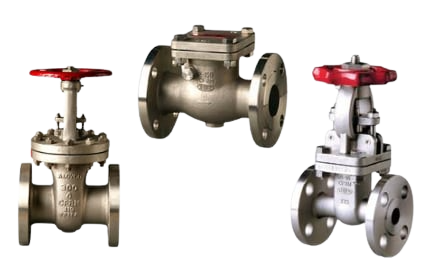

Our Products

Available Industrial Valve Products

Industrial manufacturers across sectors rely on valves that adhere to industry standards to control flow rate, pressure and more. There is a vast selection of valve types available on the market, and each type presents benefits for certain applications. For example, globe valves support flow control and leak tightness, whereas a gate valve offers simple opening and closing. MSEC offers valves in carbons steel, stainless steel, bronze, iron and many other alloys:

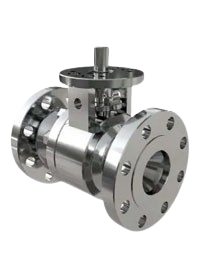

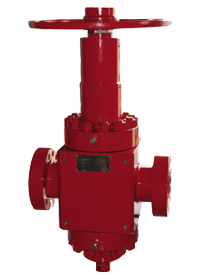

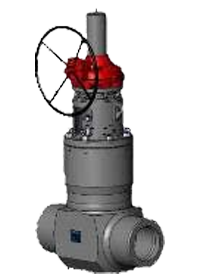

A wide range of valve types are available, such as: