- Contact Us

- Call Us

- Menu

Steam is utilized by industrial operations as a source of heat and power. Commercial and institutional facilities widely employ steam as a heating source. The overall cost of operating a steam system is generally significant, regardless of the size of the organization. Designing a system to deliver efficient performance and maintaining that performance throughout many years of expected operation requires continuous monitoring and attention.

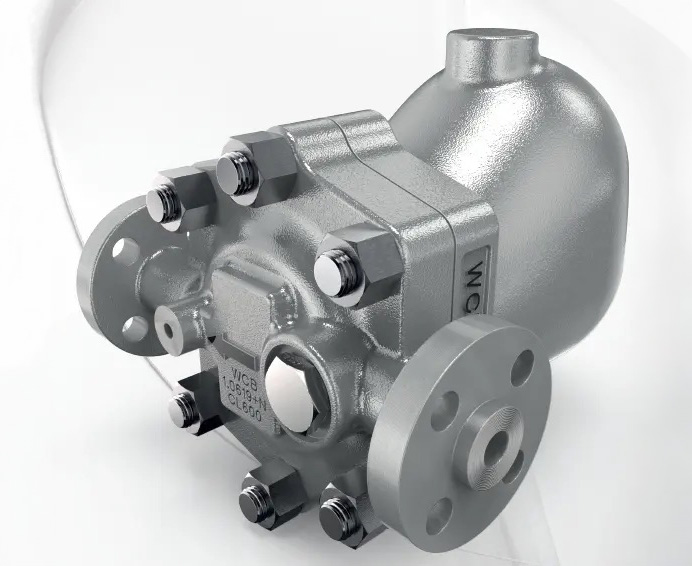

The FT62 Series, which is available with carbon steel (FTC62) or stainless steel (FTS62) body, has stainless steel internal components. It is intended for application on light and heavy condensate loads on steam systems with differential pressure up to 900 psig (62 bar). The unit includes an integral air vent and an easily maintainable in-line strainer.

More information is provided below, with a good illustration of the exterior and interior setup of the steam trap. Share your steam system requirements and challenges with experienced application specialists, combining your facility and process knowledge with their product application expertise to develop effective solutions.