Call MSEC today for peak process performance!

Contact the MSEC Experts for More Information

MSEC, Inc is ready to help plants and factories searching for an organization to deliver meaningful results to enhance industrial or commercial operations. Their dependable solutions and high-quality industrial valves streamline efficiency, reduce operational costs and preserve a secure environment.

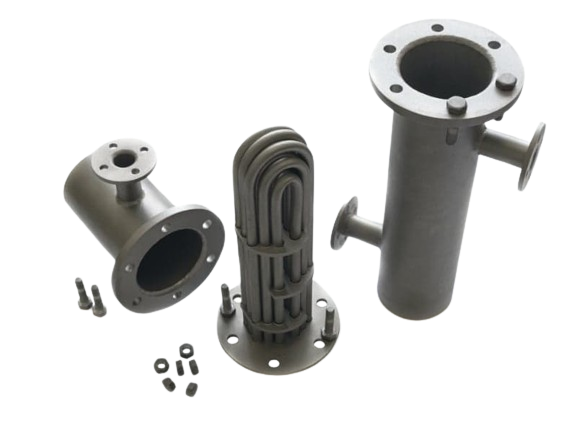

Request a quote online today to learn more about the types of Heat Transfer Equipment MSEC sells and how they can benefit your practice.

Request a Quote