- Contact Us

- Call Us

- Menu

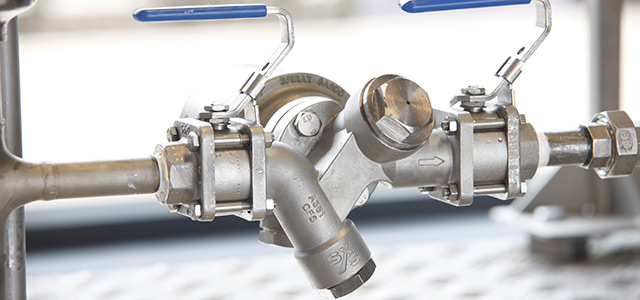

It is essential, without loss of live steam, to remove condensate and often air and other incondensable gases from steam systems. Knowing the range of steam traps allows the best choice to be made for all applications.

Thermodynamic steam traps combine reliability, simplicity and efficiency of operation; with just one moving part (a hardened stainless steel disc) they give a blast discharge with clean, tight shut-off. They are able to withstand: superheat, water hammer, corrosive condensate, freezing and vibration.

Ball float steam traps are extremely versatile and work efficiently on both light and heavy condensate loads. Although compact in size, their discharge capacity is high and continuous, ensuring maximum heat transfer. These traps are the best choice for draining plant with automatic temperature control.

An integral air vent is fitted as standard and an adjustable needle valve is available as an option to prevent steam locking.

Balanced pressure thermostatic steam traps adjust automatically to varying steam pressures and have excellent air venting characteristics during plant start-up and during normal operation. They have large discharge capacities for their size and the robust design of the internals gives a good life expectancy.

Sealed maintenance free steam traps.

Range: balanced pressure, inverted bucket and bimetallic versions.

Inverted bucket traps are the most robust type of the mechanical traps and will resist water hammer. When the check valve option has been fitted in the inlet, they can be used with superheated steam. They are available with a wide selection of valve orifices for precise pressure and load matching.

Bimetallic steam traps can conserve energy by discharging sub-cooled condensate in those applications which can utilize sensible heat. They are the most robust of all the thermostatic steam traps, being able to withstand water hammer and corrosive condensate.

For more on steam traps and condensate recovery, or for other Spirax Sarco products, contact MSEC.