- Contact Us

- Call Us

- Menu

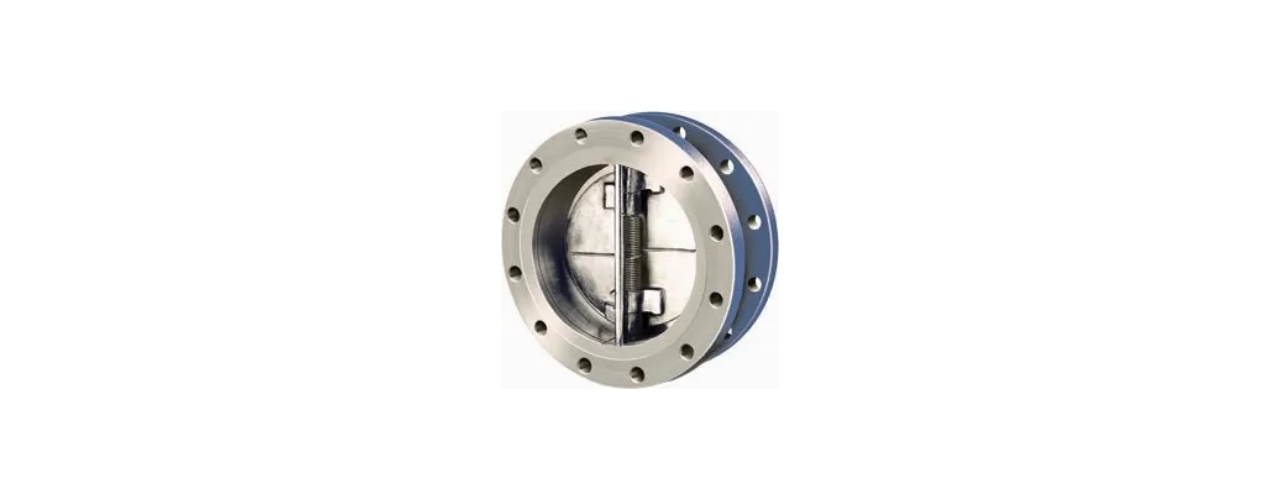

A wafer check valve is an excellent choice for applications where water hammer, mounting space and flow restriction are issues.

A wafer check is designed to be “sandwiched” inline between two pipe flanges in the piping system, adding very little additional weight or bulk to the piping layout. Wafer checks overall tend to be stronger, lighter, smaller, more efficient and less expensive than conventional swing check valves and are easier to install between standard gasket and line flanges.

Along with being lighter, easier to install and store, wafer check valves also offer the following advantages:

Wafer check valves are available in many sizes, typically from 2” to 72”, in ASME pressure classes 125 through 2500 and API 6A and 6D pressure classes. DIN, JIS, BS, AS, and ISO standards are also available. Body styles include wafer, lug, double flanged and extended body. Wafer check configurations are available in retainer-less style, wafer, extended body wafer and lined. Typical body materials are cast iron, ductile iron, WCB cast steel, 316 stainless steel and other alloys. Common seating materials are EPDM, Buna-N, Neoprene, Refrigeration-grade elastomer, and Viton. The most common end connections are raised face, plain face, ring joint, weld-end, as well as hub-end.