- Contact Us

- Call Us

- Menu

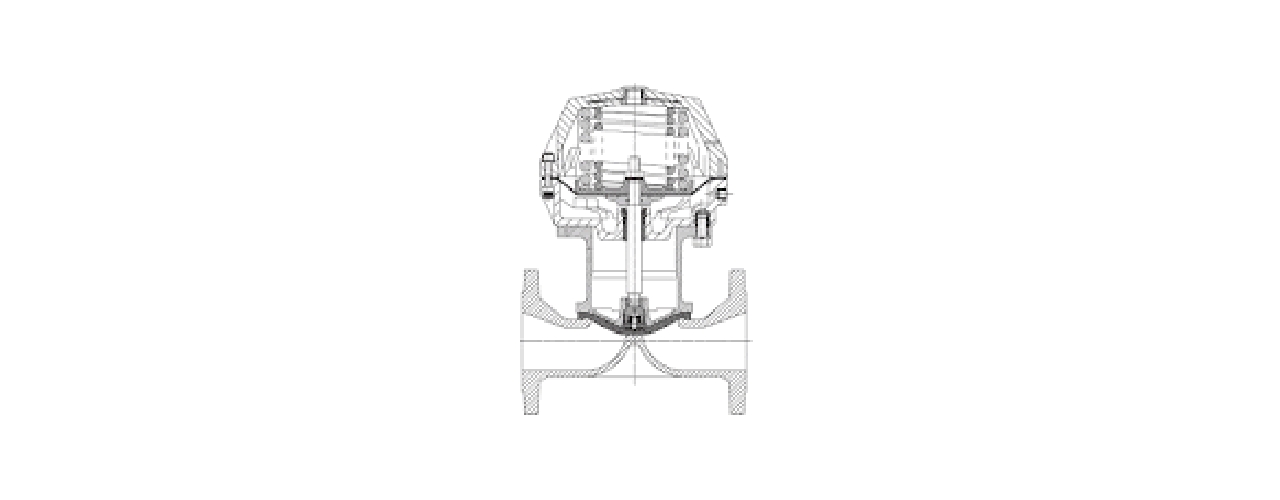

Diaphragm valves are named for the means employed in their design to restrict the path of fluid flow through the valve. Most valve designs employ a rigid solid shape which is repositioned in the fluid path to regulate flow. Diaphragm valves are somewhat unique in their use of a flexible material that is deformed by a moving part connected to the valve operating mechanism. The diaphragm acts as the flow restrictor and seat. It also isolates the valve bonnet and stem from the flowing media.

The fluid path and diaphragm positioning and seating enable this valve type to be used for throttling or simple stop operations. They are generally tolerant of particulate matter entrained in the media. Selecting body and diaphragm materials that are compatible with the media are primary elements of achieving a successful application. The diaphragm is a wearing part and should be inspected periodically and replaced when necessary.

Diaphragm valves for industrial use are available in a range of materials and sizes to accommodate light through heavy duty applications.

Share your fluid process control challenges with valve application specialists. Leverage your own knowledge and experience with their product application expertise to develop an effective solution.