- Contact Us

- Call Us

- Menu

Steam, a ubiquitous source of industrial power and commercial heat, ranks as a substantial continuing expense item for any organization where it is utilized or produced. Designing, installing, and managing steam system operation effectively can generate immense cost savings over less rigorous approaches.

An effective method of good decision-making involves tapping into the experience and expertise of those that have gone before and accomplished what you plan to attempt. For steam systems, Spirax Sarco is a premier source of information, knowledge, and expertise. The company has been deeply involved in the production and utilization of steam for many years, designing and manufacturing components utilized throughout the entire process.

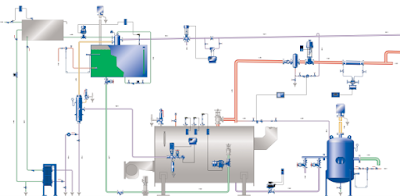

In the steam generation section of an operation, the company provides an extensive array of interrelated products.

Throughout the balance of the steam system, the list of components available from the company expands, even more, illustrating Spirax Sarco’s depth of knowledge about steam system components and how they function together to deliver efficient and safe steam system operation.

Reach out to experts with your steam system challenges, combining your facility and process knowledge with their product application expertise to develop effective solutions.