- Contact Us

- Call Us

- Menu

There are more valve selection options available than one can count. Differing types, sizes, materials, and other special characteristics distinguish each and every product as unique in its own way. Matching the design and performance strengths of a particular valve to the requirements of an application may require some investment in time and research, but the payback can be years of trouble free performance.

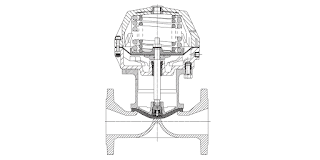

Diaphragm valves are beneficial for applications requiring hermetic isolation of the valve bonnet and stem from the media. The diaphragm serves as the isolating barrier. The valves are generally tolerant of particulate matter entrained in the media, and provide good shutoff and throttling capability.

Body and diaphragm materials should be selected that are compatible with the media. Body styles are either weir or straight through design. Straight through body styles offer a less restricted flow path than the weir type, but diaphragm movement in the weir style is reduced. Diaphragms do wear and will need to be replaced at some point. Valves should be installed with good service access.

There are many variants of diaphragm valves, broadening their suitability for a wide range of industrial applications. Share your fluid process control challenges with application specialists, combining your process knowledge with their product expertise to develop effective solutions.