- Contact Us

- Call Us

- Menu

In a closed steam system, condensate must be returned to the feedwater side of the boiler. Moving this condensate effectively through the system is essential to maintaining design performance levels throughout the system. Condensate can be considered “spent steam”, but still retains great value as preheated and treated feedwater for the boiler.

Three general methods are employed to transport condensate from where it is collected to where it is reused. If the facility layout permits, gravity can be the motive force to move the condensate back to the boiler. A second option is a mechanical pump, unsurprisingly called a condensate pump. The third common option is to employ system steam pressure to drive the condensate through the return piping and back to the boiler.

The concept of gravity return for the condensate is easy to envision….liquid flows downhill. Mechanical pumps, as well, are a well-understood means of moving liquids. When the condensate collector reaches a certain fill level, the pump is energized and the liquid is forced through the return piping.

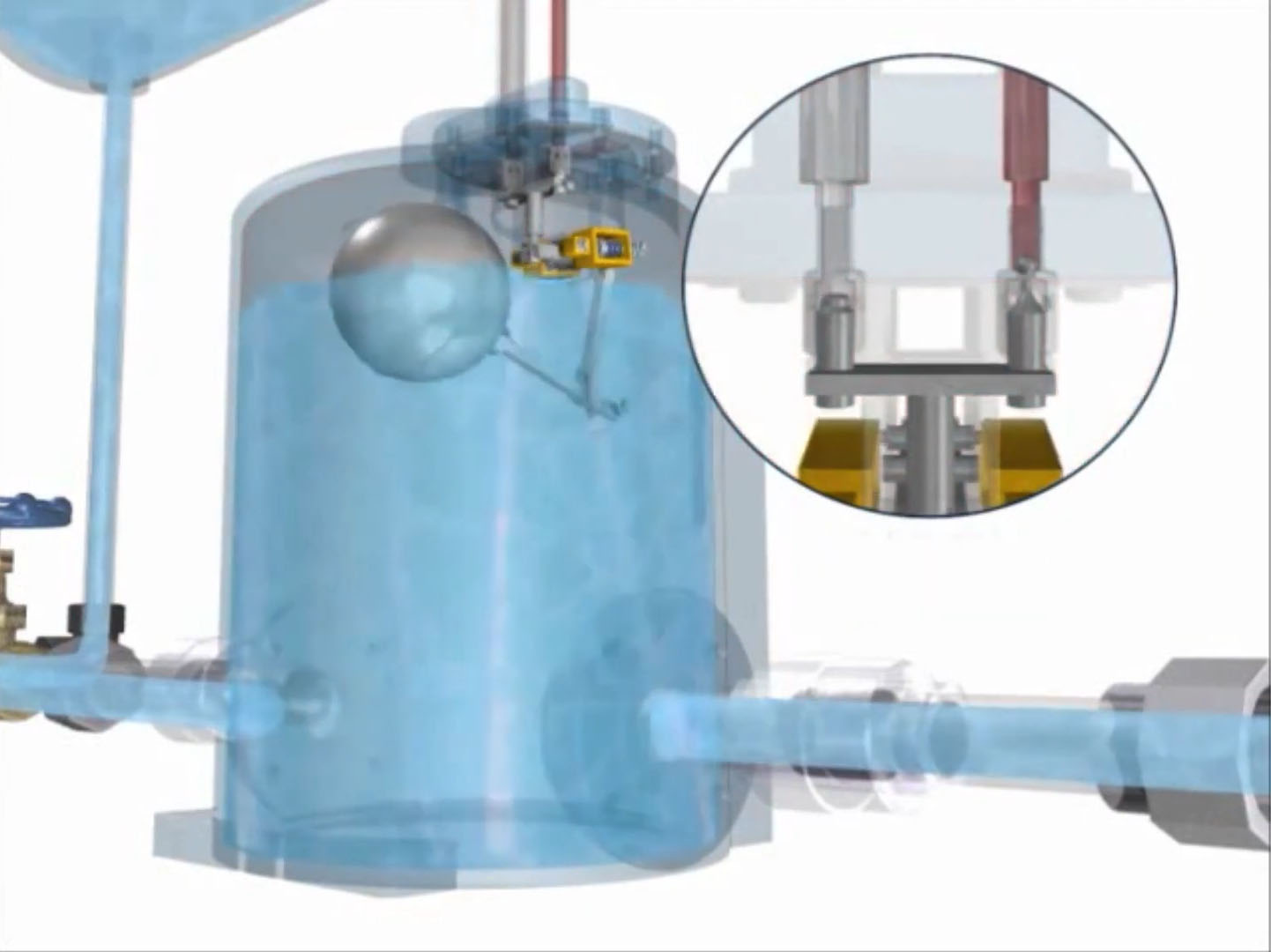

Using pressure as the motive force for condensate return involves the coordinated operation of the inlet, outlet, and vent openings to the condensate collection vessel. A float inside the collection vessel and a connected mechanism provide control of the valves at the vessel openings. In the video, you can see how the valve operating sequence provides for periods of condensate collection, then condensate discharge.

Share all of your steam system challenges with application specialists, combining your own process and facilities knowledge and experience with their product application expertise to develop effective solutions.