- Contact Us

- Call Us

- Menu

Steam is widely used throughout industrial, commercial, and institutional facilities as a means of transferring heat energy, as well as a wide array of other applications. Steam generation cost is a substantial line item on almost any balance sheet, so deriving the most efficient level of operation from a steam system pays tangible dividends.

Utilizing the heat content of steam, in a closed system, results in the production of condensate. Condensate is hot liquid water that can be returned to the boiler and re-vaporized. Managing the separation of the liquid condensate from the process steam and sending it to the lower-pressure condensate return line is the function of a steam trap. A steam trap filters out condensate (condensed steam) via an automatic valve. The trap also removes air without letting process steam escape. By filtering out the condensate and not the steam, steam waste is minimized. Steam traps generally are self-contained automatic devices. Since steam-based heating processes generally rely on latent heat transfer for rapid and efficient operation, it is necessary to continually collect and transfer condensate from the steam-containing portion of the system. The condensate will reduce heat exchanger performance if allowed to accumulate.

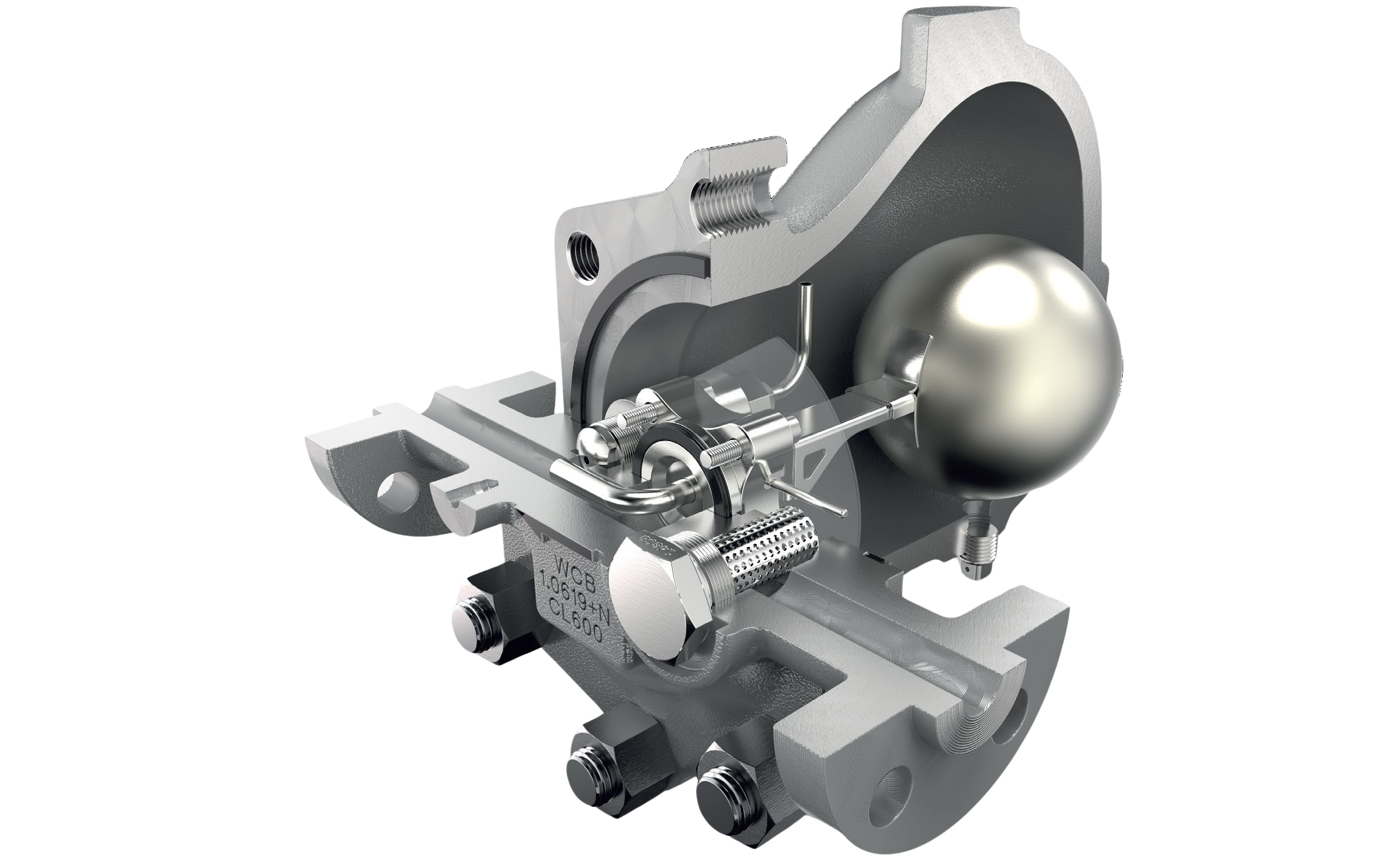

Historically, there have been three main types of steam traps: mechanical traps, thermostatic traps, and thermodynamic traps. The most commonly used mechanisms rely on differences in temperature, specific gravity, and pressure. The mechanical trap was originally developed as a bucket trap, which was a rather large trap where a bucket floated up or down to open and close a valve. Bucket traps with a lever, which face downward – also known as ‘closed bucket’ traps – are still used today as a float type trap. Processes requiring large capacities for discharge still currently use the bucket type or float type trap, with long service lives. In the modern version of a free float trap, the condensate is continuously discharged while the valve opening is constantly controlled by the amount of buoyant force acting upon a tightly sealed float.

Thermostatic traps are a smaller, more compact design. Using a temperature sensing mechanism, and operable by mechanisms like bellows or bimetal rings, these thermostatic traps have a slower response. Processes relying on rapid condensate discharge most likely will not use thermostatic traps. An example of a trap used in the process industry today is a bimetal temperature control trap. The trap includes steam tracers and will discharge when a certain condensate temperature is reached.

The core limitation of thermostatic steam traps – the slow response time – has been addressed via the development of the thermodynamic steam trap. The thermodynamic trap operates on the expansion and contraction of an encapsulated liquid. This version of the steam trap allows for the smallest amount of condensate accumulation. Early models resulted in unacceptable levels of steam loss. As a result, the commonly used disc-type trap was developed for mainstream use. The disc type is compact, versatile, and relatively affordable in terms of installation costs. In the modern disc type, pressure fluctuations in the chamber above the valve result in the valve’s opening and closing. Though in use for many years, development and refinement continue on steam traps, bringing ever-better performance to this ubiquitous steam specialty.