- Contact Us

- Call Us

- Menu

Energy conservation and energy efficiency have contributed very large cost savings to many industrial and commercial operations over the past two decades. Projects with modest payback periods quickly begin their contributions directly to the bottom line of the balance sheet. In many instances, incorporating energy conservation and efficiency measures also improve the overall functioning of the consuming systems and equipment. In order to save energy, it is generally necessary to exercise better control over equipment or system operation by gathering more information about the current operating state. This additional information, gathered through measurement instrumentation, often finds use in other ways that improve productivity and performance.

Steam is utilized throughout many industries as a means of transferring heat, as well as a motive force. Much energy is consumed in the production of steam, so incorporating ways of recovering or utilizing the heat energy remaining in waste steam is a positive step in conservation.

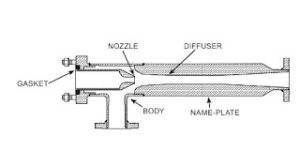

Schematic of basic thermocompressor, showing suction

Schematic of basic thermocompressor, showing suction

inlet at the bottom and high-pressure steam nozzle.

Image courtesy of Spirax Sarco

A thermocompressor is a type of ejector that mixes high-pressure steam with a lower-pressure steam flow, creating a usable discharge steam source and conserving the latent heat remaining in the low-pressure steam. The device is compact and simple, with no moving parts or special maintenance requirements. Two general varieties are available. The fixed nozzle style is intended for applications with minimal variation in the supply and condition of the suction steam (the low-pressure steam). Some control is achievable through the regulation of the high-pressure steam flow with an external control valve. A second style provides a means of regulating the cross-sectional area through which the high-pressure steam flows in the nozzle. This style is best applied when a specific discharge flow or pressure is required, or there is significant variation in the inlet steam conditions.

Share all your steam system challenges with a steam system application specialist. Combine your own process and facilities knowledge and experience with their product application expertise to develop effective solutions.