- Contact Us

- Call Us

- Menu

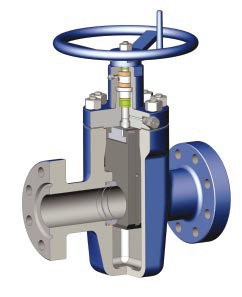

Industrial valves are manufactured in a huge array of configurations to accommodate the specialized needs of a broad range of industrial process applications. The oil and gas industry is but one segment of many throughout the industrial sphere that present its own set of application-specific criteria.

Oil and gas production, essentially pulling raw material from the earth, has unique valve performance challenges. Extreme pressure and abrasive or erosive material are common elements of oil and gas production at the wellhead. The valves also need to tolerate the range of outdoor temperatures at the production site. Safe and reliable operation throughout these and a range of other conditions are part of the design criteria for these valves. Here are some of the specific valve variants and configurations applied in the oil and gas industry at the production wellhead.

There are other specialty valves employed at or near the wellhead, but the key takeaway here is that oil and gas production generally cannot be accommodated by general-purpose valves. I have included a document below that provides additional data and engineering detail for the valves touched upon in this article. Share your oil and gas production challenges with a valve specialist. The combination of your process and production experience with their product expertise will produce effective solutions.