- Contact Us

- Call Us

- Menu

Industrial process control often involves the regulation of fluid flow. There are almost uncountable types and variants of flow control valves, each with a particular set of attributes that can make it an advantageous choice for an application.

When the process calls for controlling flow over a range of possible values, known as throttling, a globe valve may be a good candidate for the application.

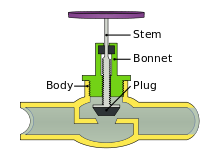

Globe valves are characterized by the change in direction of fluid flow as it passes through the valve and around the plug positioned in an opening through which fluid must pass. The plug is connected to a stem extending to the exterior of the valve body through the bonnet. Movement of the stem will reposition the plug in relation to the opening, providing a successively larger or smaller opening area through which fluid can pass.

Globe valves are available in tee, angle, and wye configurations, as well as an enormous range of special configurations, to suit specific applications.

What are some potential advantages of globe valves?

Higher valve pressure drop than some other designs

When flow throttling capability is the overriding concern for an application, a globe valve is a good candidate for consideration. Share your flow control challenges with valve and automation specialists. Combining your process knowledge and experience with their product application expertise will produce effective solutions.