- Contact Us

- Call Us

- Menu

Check valves are used in fluid systems to ensure flow in one direction and prevent backflow. They protect crucial fluid system components, including other valves, pumps and piping. In addition to ensuring the unidirectional flow of fluids, these valves maintain the integrity and efficiency of pipelines. Swing check valves are available in various sizes, designs and materials to suit specific applications.

The following guide discusses the swing check valve’s working principles, key features, advantages, disadvantages, applications and installation information to help you select the best options for your unique applications.

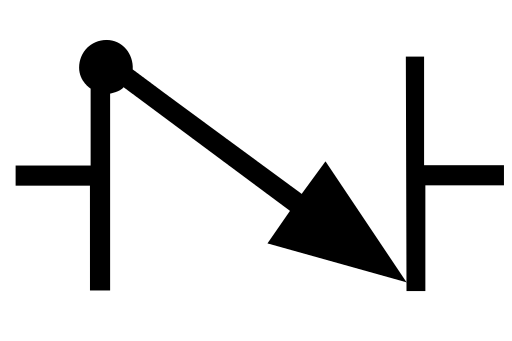

The swing check valve is a mechanical valve that utilizes a swinging disc to allow forward flow and block reverse flow. The components of a swing check valve include:

The disk is hinged at the top of the valve body by the arm and the pivot pin is attached through the arm to allow the disk to hang in place. The disc swings freely on a pivot, opening when the fluid flows in the desired direction and closing when it flows in reverse.

The disk has a 360-degree range and only opens at a specific minimum pressure known as the cracking pressure, which is applied under the seak and disk. When fluid flow stops and the cracking pressure reduces, gravity shuts the disk closed against the seat. Later, when the fluid attempts to reverse, the pressure forces the valve to close completely against the seat, preventing backflow. The arm may be weighted, or a spring can be installed over the arm to assist in closing the valve.

Swing check valves are categorized according to the operating procedure. Therefore, there are two main swing check valve categories:

Installing swing check valves has several advantages for fluid systems, which include:

Swing check valves may not be suitable for particular systems. They cannot eliminate water hammer occurrence because the discs have a significant distance to cover between the fully open and closed positions, and they’re not a good option where there’s pulsating or reversed fluid. Swing check valves are also slower than lift and spring check valves.

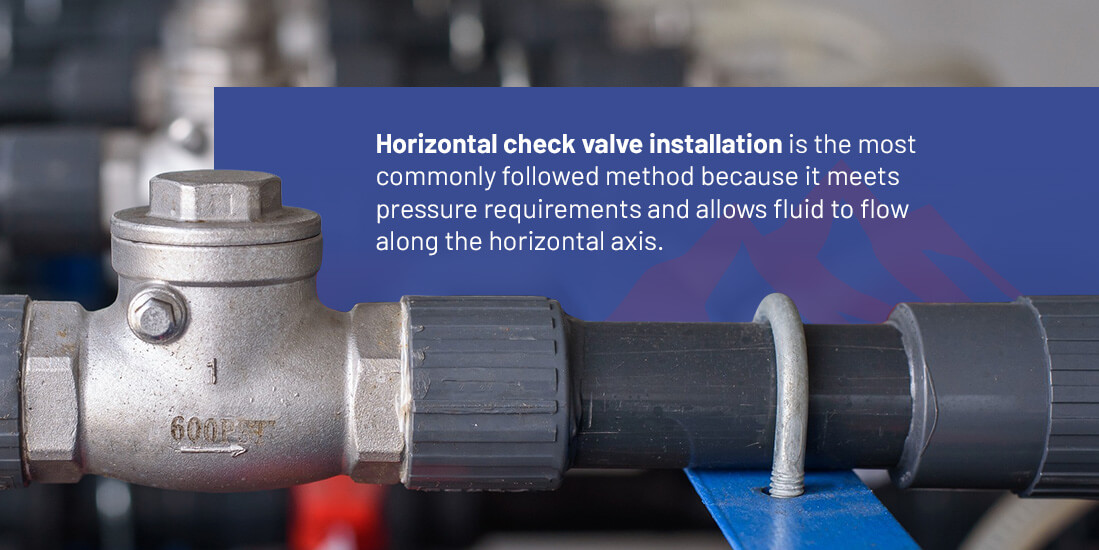

The most crucial factors to consider when installing swing check valves are the flow direction, pressure and nature of the fluid. If these factors are not considered, they may lead to catastrophic failure. Horizontal check valve installation is the most commonly followed because it meets pressure requirements and allows fluid to flow along the horizontal axis.

However, some applications still require vertical installation, which means the effect of gravity on the system must be considered. Vertically installing a swing check valve increases the risk of water hammering because gravity may forcefully slam the valve against the seat, disrupting the flow and causing resistance inside the pipes. Additionally, vertical swing check valves are only effective with an upward-flowing fluid system.

The installation procedure varies from project to project based on the factors mentioned above and the type of connection. However, the following steps act as guidelines for swing check valve installation regardless of the connection:

After installation, the swing check valves require minimal maintenance through routine visual inspections to check for wear, rust, leaks and debris on the valve body and disc. In case of damage, these parts should be replaced promptly. Occasional cleaning of the valve disc and body also helps to minimize debris and buildup that may interfere with optimal performance.

Swing check valves are used in numerous industries. They can be made from various materials, including stainless steel, carbon steel, ductile iron, cast steel brass and bronze. PVC and ABS swing check valves are also cost-effective for applications with temperatures under 100 degrees Celsius (212 degrees Fahrenheit).

They’re generally suitable for applications in systems that facilitate the flow of clean and non-solid state medium, ranging from petroleum, water, acid and chemicals.

Primarily, swing check valves are used for water supply, wastewater pumping and slurry transport because they are less likely to clog or block. More specifically, swing check valves are employed in the following industries:

MSEC Inc. is a leading process equipment distributor and service provider partnered with some of the top manufacturers and valve distributors. Our inventory includes the Duo-Chek® high-performance non-slam check valves in different sizes, configurations and pressure classes. These are smaller, lighter and more efficient for demanding applications than conventional swing check valves.

With our Valve™ AID services, MEC can help customers gather valuable data on their critical valves with around-the-clock access to stay efficient during planned and unplanned downtime.

Contact us today for more information about Duo-Chek® valves and other industrial swing check valves at MSEC Inc.