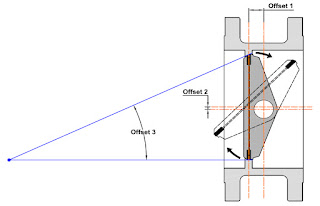

As the name implies, there are three separate offsets designed into the triple offset valve. Two of the offsets apply to the location of the shaft with respect to the center line of the bore and the center line of the disc/seat sealing surfaces.

The third offset in the design is the axis of the seat cone angle that is inclined from the center line of the valve bore. This eliminates rubbing of the seat/seal contact surfaces during operation and preserves sealing integrity over the cycle life of the valve.

The contact is made in only the final point of closure, acting as a mechanical travel stop which prohibits over-travel of the disc.

Applications and Method of Control

A triple eccentric or triple offset butterfly valve should be used when the application requires bubble tight shut-off, but does not allow the use of a rubber-lined butterfly valve due to low/high temperatures and high pressure. The triple offset design can be used for on/off services, throttling services and modulating services.

On/Off Service

Like the name suggests, on/off valves are designed to shutoff and to open fully but lack the ability to to regulate effectively through the range of travel.

Throttling Service

Throttling service (sometimes referred to as inching) is in general flow control through the system where the valve is set and held in an intermediate position.

Modulating Service

Modulating service (known also as regulating service) is used to drive the valve frequently to any position between fully open and fully closed to control the flow. It uses feedback from the field, and valve disc position is adjusted almost continuously.

Quarter turn valves are usually limited to a throttling range of ~25° to ~75° open (25% to 85%). In case of throttling the manufacturer should be consulted in order to predict whether the control valve was installed accurately.

For more information, contact MSEC.